Installing solar panels on any roof can be challenging. For this remarkable project the PV modules were attached to a trellis of I-beams 25 feet above the roof deck of a six-story medical center during the present COVID-19 pandemic.

Like a jigsaw puzzle that needs all of the pieces to seamlessly fit together, the Sun Light & Power (SLP) installation team at the UCSF Medical Center project in Mission Bay had to work safely, meticulously, according to the project schedule, and in close coordination with the other subcontractors on the roof. And like any other SLP project, the team – composed of James Watt, Jack Lai, Cristobal Gomez, Roni Magzianov, Bryan LeSueur, Malcolm Jenkins and Damone Taylor – rose to the challenge.

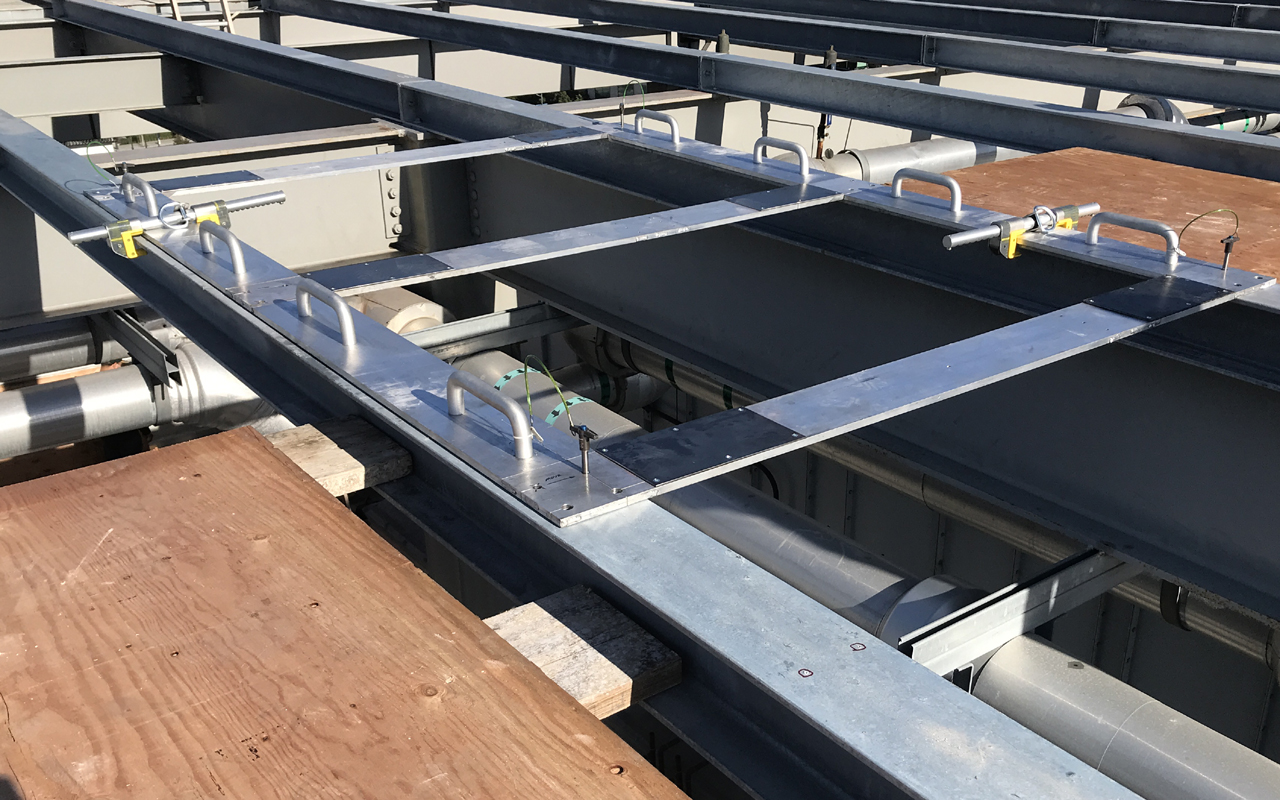

Extensive planning was required to install the 678 SunPower X22-360-COM PV modules on the 176x82-foot installation area. Due to the very low margin of error – only a quarter of an inch – the SLP team and TCB Builders designed a special metal jig that allowed them to accurately and easily mark the mounting holes for the solar panel brackets. The jig had multiple indentations that the crew used to mark the holes on the I-beams. Once the markings were made, the team slid the jig to mark the holes for the next module. After the iron workers drilled the holes, our solar team returned and installed the PV modules using a wooden platform made of specially-engineered scaffolding planks. This platform was placed on the I-beams, giving the installers a safe space to work underneath the solar panels. And since the modules were installed facing east-west to maximize power density per square foot, the tighter footprint meant that our crew couldn't walk between the modules after each row was installed.

Extensive planning was required to install the 678 SunPower X22-360-COM PV modules on the 176x82-foot installation area. Due to the very low margin of error – only a quarter of an inch – the SLP team and TCB Builders designed a special metal jig that allowed them to accurately and easily mark the mounting holes for the solar panel brackets. The jig had multiple indentations that the crew used to mark the holes on the I-beams. Once the markings were made, the team slid the jig to mark the holes for the next module. After the iron workers drilled the holes, our solar team returned and installed the PV modules using a wooden platform made of specially-engineered scaffolding planks. This platform was placed on the I-beams, giving the installers a safe space to work underneath the solar panels. And since the modules were installed facing east-west to maximize power density per square foot, the tighter footprint meant that our crew couldn't walk between the modules after each row was installed.

The COVID-19 pandemic required an additional layer of safety precautions. Each team member had to answer screening questions for COVID-19 at the start of every workday, and had to wear proper PPE such as masks and eyewear. To work within the dropdown ceiling while running the electrical conduit from the AC disconnect switch at the loading dock to the electrical room on the ground floor, the installers had to work inside an airtight cart to ensure that potentially infectious particles did not enter the hospital.

The COVID-19 pandemic required an additional layer of safety precautions. Each team member had to answer screening questions for COVID-19 at the start of every workday, and had to wear proper PPE such as masks and eyewear. To work within the dropdown ceiling while running the electrical conduit from the AC disconnect switch at the loading dock to the electrical room on the ground floor, the installers had to work inside an airtight cart to ensure that potentially infectious particles did not enter the hospital.

Federal Aviation Administration flight restrictions prohibited the SLP crew from using a crane to lift the solar panels to the roof. Instead, all materials and equipment had to be carefully and painstakingly brought up through the service elevator and then to the roof area via a ladder lift.

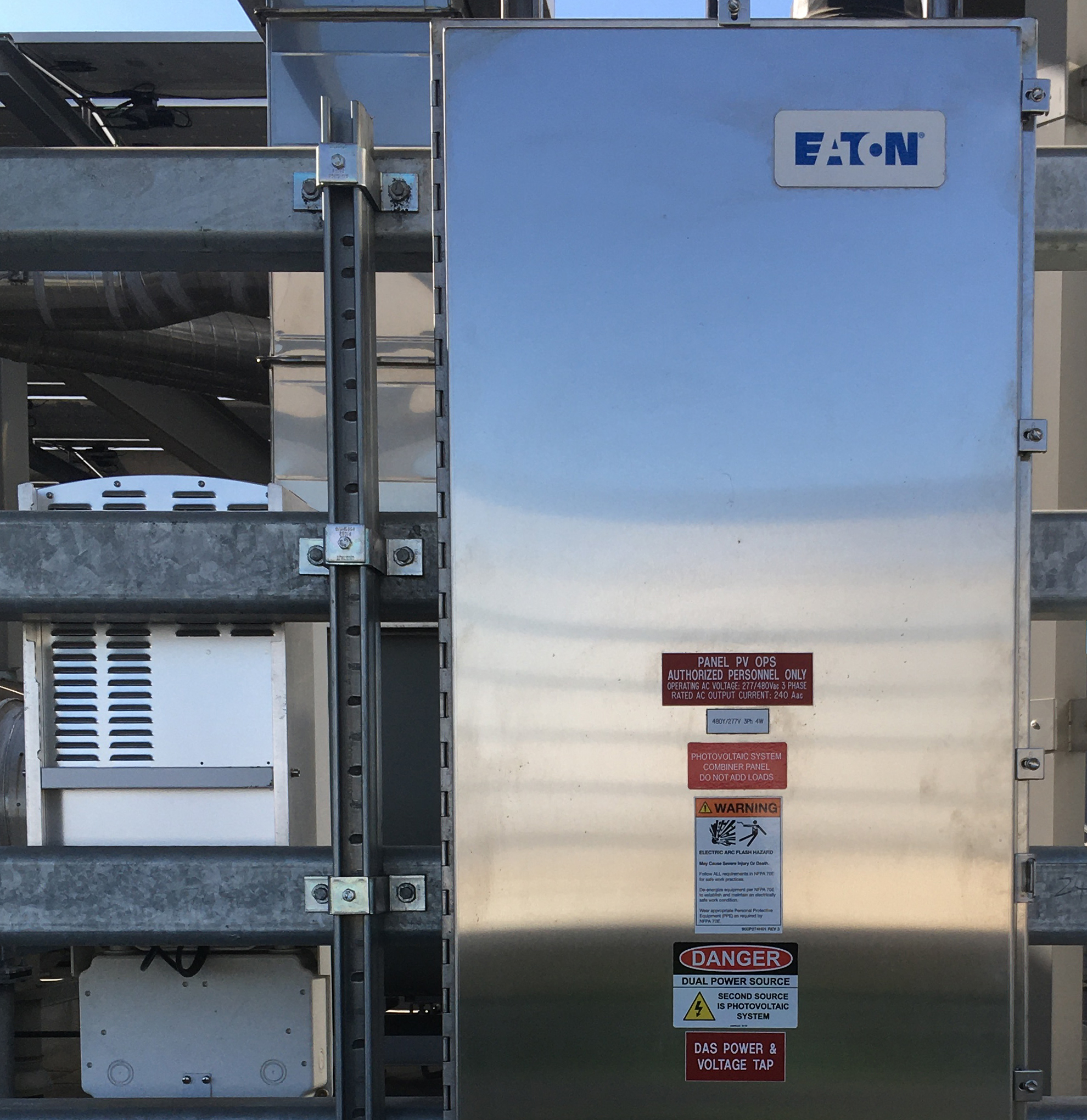

SLP also had to ensure strict compliance with the approved material and equipment list from Solar Design Associates. Because UCSF is located only half of a mile from the salty San Francisco Bay, all exterior conduit had to be vinyl-coated, while the distribution panel, AC disconnect, and gutters underneath the inverters had to be made of stainless steel in order to avoid corrosion.

SLP also had to ensure strict compliance with the approved material and equipment list from Solar Design Associates. Because UCSF is located only half of a mile from the salty San Francisco Bay, all exterior conduit had to be vinyl-coated, while the distribution panel, AC disconnect, and gutters underneath the inverters had to be made of stainless steel in order to avoid corrosion.

The employee owners of Sun Light & Power would like to thank UCSF, Solar Design Associates, TCB Builders and all of the other subcontractors that made this unique and remarkable project possible. We are very proud of our field crew for their expertise, ingenuity and dedication as they worked through the many challenges that faced them during this installation. Our Marketing Team would also like to acknowledge the beautiful photographs that our team captured prior to the ash fall that resulted from the record breaking wildfires this year. For more photos visit our UCSF project page.

Marge Maceda is Sales Operations Lead and Salesforce Administrator at Sun Light & Power.

Photographs by Sun Light & Power PV Foreperson Jack Lai and Superintendent James Watt.

Do you have a challenging solar project? Call us for a quote today!